KHS Introduces AI-Driven Solutions for Bottle Cap Inspection

- KHS is integrating artificial intelligence to enhance inspection technology.

- The EU mandates tethered caps for single-use PET bottles by July 2024.

- AI-based defect detection improves accuracy in cap inspection systems.

- High-resolution cameras and deep learning are key components of the system.

- KHS plans to expand AI applications to other inspection technologies.

AI Aims to Revolutionize Bottle Cap Inspection

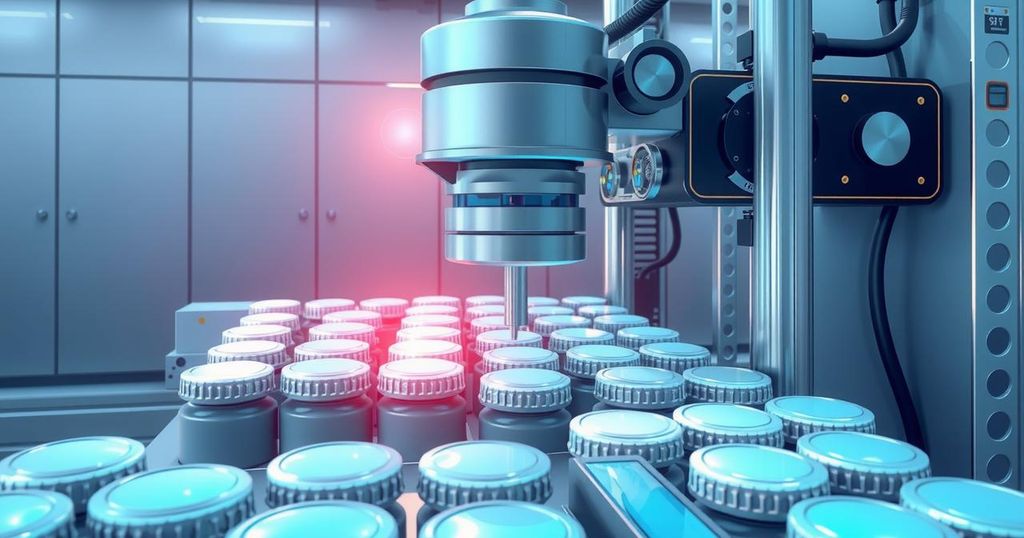

KHS is taking a significant step by integrating artificial intelligence into their inspection technology. This move comes as the European Union mandates tethered caps for all single-use PET bottles, a requirement that takes effect in July 2024. The challenges posed by such a variety of closure options and escalating inspection demands have prompted KHS to enhance its inspection offerings, specifically with the Innocheck TSI closing inspection system.

New Challenges in the Beverage Industry

The introduction of tethered caps brought a storm of change across the beverage industry in Europe. It was a head-scratcher for many producers who now have to rethink their entire approach to bottle caps and product quality. Nikita Wall, who works in product support for labeling and inspection technology at KHS, highlights that “These caps were hardly used before the EU’s regulations, and existing systems struggled to cope with the new inspection demands.” This shift has not just impacted the caps but also the technology that checks for proper capping, making AI-powered solutions essential for staying ahead.

The Future of Inspection Technology

At the heart of KHS’s innovation is their AI-driven defect detection feature, designed specifically for handling tethered caps. This clever solution analyzes images of bottle caps using patent-pending algorithms that process data in real-time. High-resolution cameras scan the caps, and deep learning models enrich the system by adapting to new defect patterns as they arise. This means that the KHS inspection system is not only more accurate but also more efficient, addressing the high quality demands of its clients, Wall points out that their extensive field tests endorse the AI’s capabilities, ensuring it meets rigorous product standards. The adaptability of this technology allows it to be integrated into both existing and new machines, pushing the boundaries of what’s possible in inspection technology.

Expanding AI Capabilities in KHS Systems

KHS seems to have a finger on the pulse of innovation, with plans to expand the application of AI in other inspection systems down the line. Conversations are underway within their development team to identify potential areas where AI can add value. Wall insists, “AI tools should be employed where they can effectively handle complex demands and yield tangible benefits for our customers.” This innovation mirrors the company’s commitment to addressing the evolving needs in the beverage sector, ultimately shaping a smarter future for product quality and assurance.

KHS is embracing artificial intelligence to tackle the challenges arising from the EU’s new tethered cap regulations. Their Innocheck TSI closing inspection system now features advanced AI-based defect detection, which enhances both accuracy and efficiency. Looking to the future, KHS plans to expand AI utilization across different inspection technologies, signaling a broader commitment to innovation in the beverage industry.

Post Comment