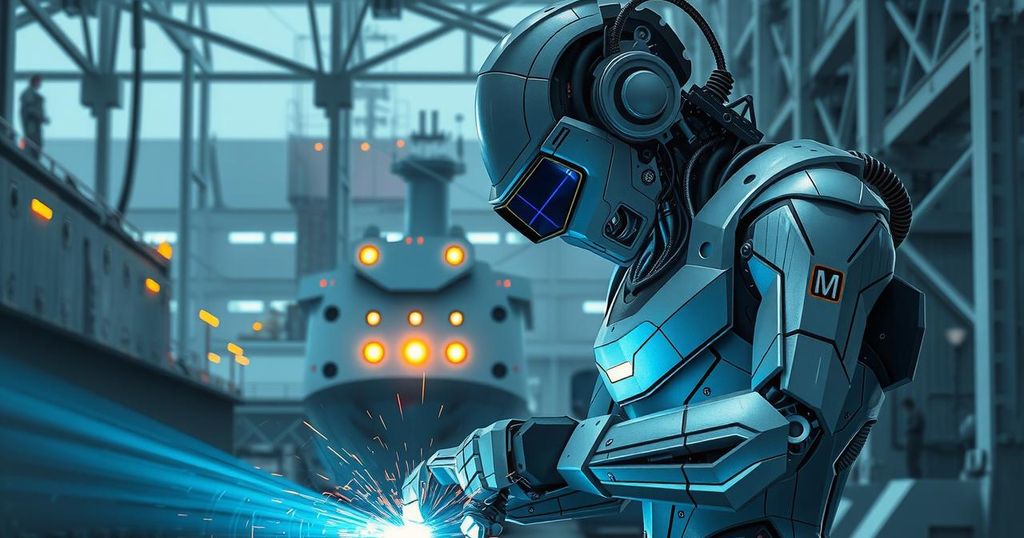

HD Hyundai Group Partners with AI Companies to Create Advanced Welding Humanoids

HD Hyundai Group has joined forces with AI companies to develop advanced welding humanoids for shipbuilding. The companies plan to create prototypes by 2026, focusing on improving efficiency and worker safety in shipyards. This collaboration emphasizes a significant shift towards automation and intelligent robotics in the industry.

In a significant move for the shipbuilding industry, HD Hyundai Group has partnered with AI companies to create advanced welding humanoids. Announced on the 8th of this month, the collaboration brings together HD Korea Shipbuilding & Marine Engineering, HD Hyundai Robotics, Persona AI, and Basil Company. This joint venture aims to push the boundaries of automation by developing robots capable of precise welding tasks.

The memorandum of understanding (MOU) set up between these companies lays the groundwork for building humanoids that utilize artificial intelligence and sophisticated robotic technology. While HD Hyundai Samho Heavy Industries is already using welding robots, the objective here is to innovate beyond traditional capabilities. The end goal? Enhanced efficiency in shipyard production and improved worker safety.

So, what roles will each company play in this ambitious project? HD Hyundai Robotics will leverage its AI-based welding automation technology to verify robot performance. Meanwhile, HD Korea Shipbuilding & Marine Engineering will conduct tests of the humanoids within actual shipyard settings, providing valuable data and tech support for real-world applications.

On the other hand, Persona AI is tasked with crafting the humanoid hardware and developing the necessary AI control and learning algorithms. Basil Company rounds out the team by focusing on the creation of specialized welding tools for the humanoids and constructing test platforms for them.

The timeline for this project looks ambitious. The team intends to have prototypes ready by 2026, with hopes to transition into full-scale demonstrations and potential commercialization by 2027. High hopes and high stakes are in play, as their innovations could transform the landscape of shipbuilding.

An HD Hyundai representative asserted, “Welding humanoids will not only improve productivity but also reduce the burden on workers and dramatically increase safety.” This means not just a leap in technology; it also signals a shift toward a new era of shipbuilding automation designed for the frontline workers.

Perspectives from the companies reveal a shared vision. Nick Radford, CEO of Persona AI, noted, “Applying AI technology to core processes in the shipbuilding industry is a very meaningful challenge.” He added that the goal is to create a smart shipyard where humans and robots work in harmony, blending intelligence with traditional craftsmanship.

Kim Sung-won, the CTO of Basil Company, shared his enthusiasm about the advancements to come, saying, “We will develop humanoids capable of precision welding to raise the level of automation in the shipbuilding industry to the next level.” It’s a statement that not only highlights confidence in technology but also underscores the growing importance of innovation in an ever-evolving sector.

HD Hyundai Group’s collaboration with AI firms may mark a pivotal moment in the shipbuilding realm. By aiming to advance welding humanoids with the power of AI, the project promises not just enhanced productivity but also a safer environment for workers. With prototypes expected by 2026 and a shift to commercialization in 2027, this initiative could reshape how ships are built for years to come.

Original Source: www.mk.co.kr

Post Comment